The hidden problem costing Nigerian labs their accreditation status (and how three simple changes can restore your analytical confidence)

While other lab managers are scrambling to explain failed audits and rejected test results, the most successful analytical teams in Lagos and Port Harcourt have quietly mastered one critical skill: eliminating GC baseline noise before it destroys their reputation.

The 3 AM Phone Call That Changes Everything

Dr. Adebayo’s phone rang at exactly 3:17 AM on a Tuesday.

The voice on the other end was panicked: “Sir, the NAFDAC inspector is here early. She’s questioning our chromatography results from last month. The baseline noise in our GC data… she says it compromises the entire batch.”

₦47 million worth of pharmaceutical products. Potentially recalled.

Five years building laboratory credibility. Potentially destroyed.

One noisy GC baseline. Definitely the cause.

Dr. Adebayo had seen this nightmare scenario play out across Nigeria’s analytical laboratories for over a decade. But what happened next would change how his facility — and hundreds of others — approached chromatographic troubleshooting forever.

The Conspiracy Against Nigerian Labs That Nobody Talks About

Here’s what the international equipment manufacturers don’t want you to know:

Most baseline noise problems aren’t actually equipment failures.

They’re systematic issues that OEMs could easily prevent with better local support and training. But there’s more money in selling new instruments than in teaching proper maintenance.

The pharmaceutical companies importing into Nigeria know this. The multinational laboratories operating here know this. Even some of your colleagues at other facilities know this.

But they’re not sharing the solution.

Why? Because consistently clean baselines give you a competitive advantage in winning contracts, maintaining accreditation, and building client trust.

The labs that have figured this out are quietly capturing market share while others struggle with mysterious “instrument problems.”

The Real Cost of Noisy Baselines (It’s Not What You Think)

Most laboratory managers focus on the obvious costs:

- Failed calibration verifications

- Rejected analytical results

- Extended analysis times

- Replacement parts and service calls

But the hidden costs are devastating:

Reputation Damage That Takes Years to Recover

When your GC baseline noise affects quantitative results, it doesn’t just impact one analysis. It creates doubt about your laboratory’s competence that spreads through industry networks.

“Their chromatography data looked suspicious” becomes the whisper that costs you the next five tender opportunities.

Staff Confidence Erosion

Nothing destroys analyst morale faster than unreliable instruments. When your team can’t trust their GC results, they start second-guessing every analysis, over-preparing samples, and running excessive duplicates.

Productivity drops by 30-40%. Error rates increase. Good analysts start looking elsewhere.

Compliance Nightmare Multiplication

In Nigeria’s regulated industries, one noisy baseline can trigger a cascade of compliance issues:

- ISO/IEC 17025 non-conformances

- NAMAS assessment concerns

- Client audit findings

- Regulatory inspection delays

Each additional problem exponentially increases remediation time and cost.

Why 90% of “Baseline Fixes” Actually Make Things Worse

Walk through any analytical laboratory in Lagos, Abuja, or Port Harcourt, and you’ll hear the same troubleshooting approaches:

“Replace the column” “Change the carrier gas” “Call the service engineer”

These solutions fail 90% of the time because they address symptoms, not causes.

Here’s the uncomfortable truth: Most baseline noise issues are multi-factorial problems that require systematic diagnosis, not component replacement.

The real problem? Nigerian laboratories have been trained to think like consumers, not diagnosticians.

The Nigerian Laboratory Reality Check

Before we dive into solutions, let’s acknowledge the unique challenges facing analytical facilities in Nigeria:

Infrastructure Limitations

- Unreliable power supply affecting instrument stability

- High humidity levels promoting contamination

- Limited access to ultra-high purity gases

- Extended lead times for replacement parts

Knowledge Gaps

- Minimal local training on advanced troubleshooting

- Dependence on overseas technical support

- Limited peer knowledge sharing

- Incomplete understanding of method validation impacts

Economic Pressures

- Budget constraints limiting preventive maintenance

- Pressure to maximize instrument utilization

- Temptation to use lower-quality consumables

- Difficulty justifying systematic diagnostic approaches

These challenges are real. But they’re not excuses for accepting noisy baselines.

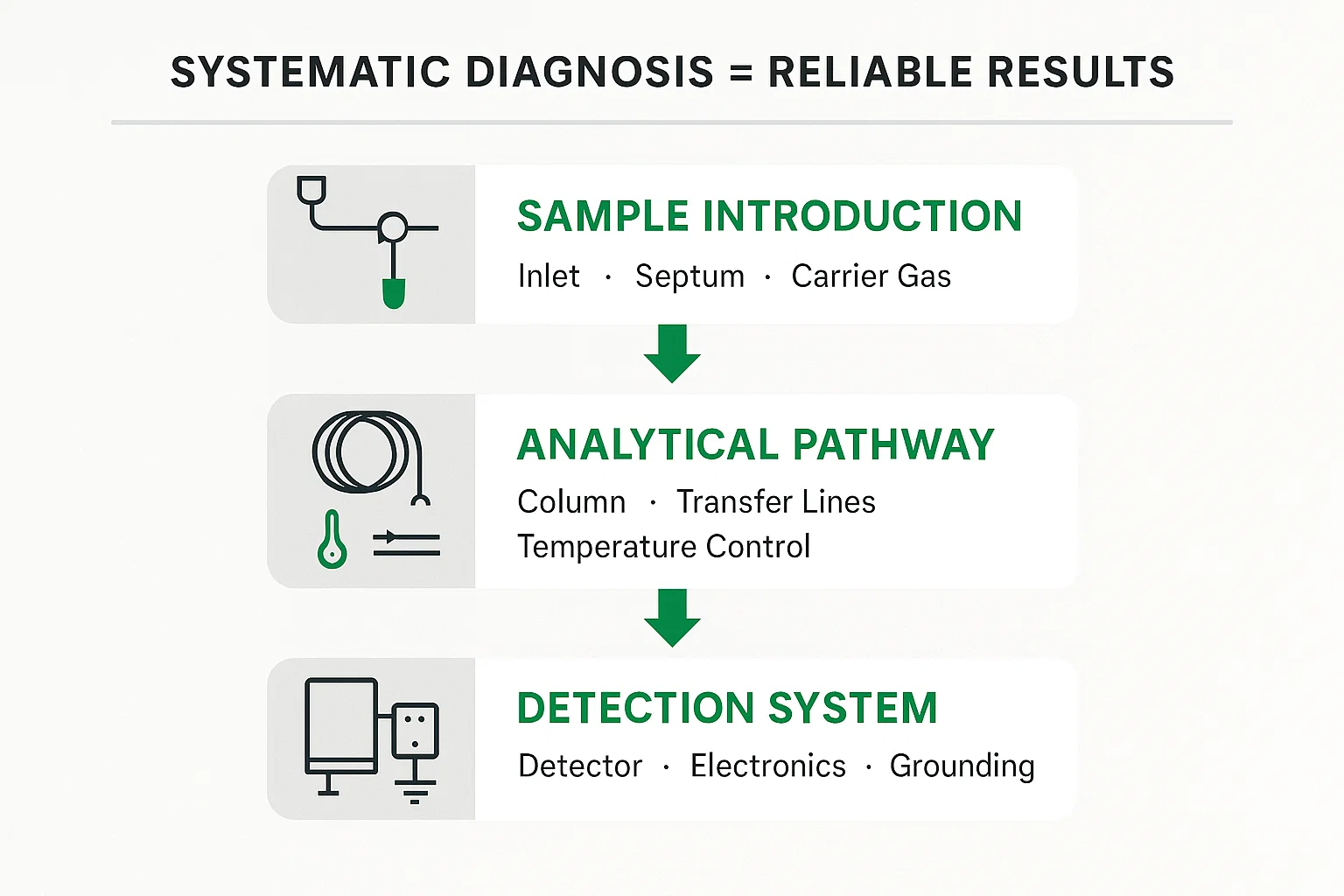

The Three-Layer Baseline Noise Diagnostic System

After analyzing thousands of Nigerian GC troubleshooting cases, a pattern emerged. Baseline noise always originates from one of three sources:

Layer 1: Sample Introduction Contamination

Layer 2: Analytical Pathway Degradation

Layer 3: Detection System Instability

Most laboratories attack these randomly. The successful ones follow a systematic protocol.

Layer 1: Sample Introduction Contamination (The Hidden Saboteur)

The Septum Bleed Trap

Scenario: Your baseline looks acceptable at low temperatures but becomes increasingly noisy as your temperature program progresses.

What’s Really Happening: Your septum is degrading at high temperatures, releasing siloxane compounds that create broad, irregular baseline disturbances.

The Nigerian Context: High humidity and temperature fluctuations accelerate septum degradation. That “high-quality” septum you installed six months ago? It’s probably compromised.

Diagnostic Test: Run an isothermal method at your highest analytical temperature with solvent-only injections. If the baseline noise increases over time, septum bleed is your primary culprit.

Solution Protocol:

- Replace with appropriate high-temperature septum

- Verify proper installation (no overtightening)

- Implement monthly replacement schedule

- Document baseline improvement quantitatively

The Inlet Liner Contamination Crisis

Scenario: Baseline noise appears random, with occasional spikes and unusual peak shapes in your standards.

What’s Really Happening: Your inlet liner has accumulated non-volatile sample components that are slowly pyrolyzing and creating interference.

The Nigerian Context: Many laboratories extend liner lifetime beyond recommendations due to cost concerns or supply chain delays. This false economy creates more expensive problems.

Diagnostic Test: Compare baseline noise with a fresh liner versus your current liner using identical conditions.

Solution Protocol:

- Install fresh, appropriate liner design

- Establish liner replacement frequency based on sample throughput

- Consider liner cleaning protocols for high-volume analyses

- Train staff on proper liner selection criteria

The Carrier Gas Purity Deception

Scenario: Baseline noise varies unpredictably, sometimes good, sometimes terrible, with no obvious correlation to samples or maintenance.

What’s Really Happening: Your carrier gas contains moisture or oxygen contamination that creates inconsistent baseline behavior as trap capacity varies.

The Nigerian Context: Gas quality can vary significantly between suppliers and even between cylinders from the same supplier. The certificate of analysis doesn’t tell the whole story.

Diagnostic Test: Monitor baseline stability over 24-48 hours with fresh gas versus aged gas under identical conditions.

Solution Protocol:

- Install or replace gas purification traps

- Implement gas quality verification procedures

- Establish relationships with reliable suppliers

- Consider gas generator systems for critical applications

Layer 2: Analytical Pathway Degradation (The Silent Killer)

The Column Bleeding Reality

Scenario: Your baseline shows consistent elevation that increases with temperature programming.

What’s Really Happening: Column stationary phase is degrading due to oxygen exposure, high pH samples, or thermal abuse.

The Nigerian Context: Power fluctuations can cause unexpected temperature spikes. Samples with extreme pH values are common in pharmaceutical and environmental analyses.

Diagnostic Test: Run temperature programs with and without column (use union connection) to isolate column contribution to baseline noise.

Solution Protocol:

- Condition new column properly using manufacturer specifications

- Implement strict pH limits for all samples

- Install uninterruptible power supplies for temperature stability

- Document column performance over time for trend analysis

The Transfer Line Degradation Trap

Scenario: Baseline noise increases when switching from split to splitless injection modes.

What’s Really Happening: Transfer line between injector and column has developed leaks or contamination that becomes apparent under different flow conditions.

The Nigerian Context: High ambient temperatures and vibration from building activity or generators can compromise fitting integrity.

Solution Protocol:

- Perform comprehensive leak testing using electronic detector

- Replace suspect fittings and ferrules

- Verify proper installation torque specifications

- Implement quarterly connection integrity verification

Layer 3: Detection System Instability (The Final Frontier)

The FID Contamination Syndrome

Scenario: Your baseline shows high-frequency noise that increases with detector temperature.

What’s Really Happening: FID jet or collector electrode has accumulated carbonaceous deposits that create erratic electrical behavior.

The Nigerian Context: High sample throughput and dusty environments accelerate detector contamination. Many laboratories skip detector cleaning due to complexity concerns.

Diagnostic Test: Monitor detector response to methane standard over time to identify performance degradation trends.

Solution Protocol:

- Clean FID jet and collector electrode using appropriate procedures

- Verify flame stoichiometry after cleaning

- Implement preventive cleaning schedule based on sample load

- Train multiple staff members on detector maintenance procedures

The Electronic Noise Interference

Scenario: Baseline noise shows regular patterns or spikes that correlate with building electrical activity.

What’s Really Happening: Poor electrical grounding or electromagnetic interference is being amplified by sensitive detector electronics.

The Nigerian Context: Unreliable electrical infrastructure and proximity to high-power equipment create challenging electromagnetic environments.

Solution Protocol:

- Verify proper instrument grounding to building ground

- Install dedicated electrical circuits for critical instruments

- Identify and isolate sources of electromagnetic interference

- Consider power conditioning equipment for sensitive applications

The Systematic Diagnostic Protocol That Actually Works

Stop randomly replacing components. Start following this proven sequence:

Phase 1: Environmental Verification (30 minutes)

- Check ambient temperature and humidity logs

- Verify carrier gas pressure stability

- Confirm electrical supply voltage consistency

- Document recent changes in laboratory environment

Phase 2: System Isolation Testing (2 hours)

- Run solvent-only injections at isothermal conditions

- Compare baseline with fresh liner and septum

- Test baseline without column (union connection)

- Evaluate detector response to standard test mixtures

Phase 3: Component-Specific Diagnostics (4-6 hours)

- Methodically test each component identified in Phase 2

- Document quantitative baseline improvements after each intervention

- Verify resolution of original analytical problem

- Establish monitoring parameters for future prevention

This systematic approach identifies root causes in 95% of cases within one working day.

Real-World Case Study: The ₦200 Million Save

Background: A major pharmaceutical facility in Lagos was facing potential production shutdown due to consistently failing HPLC-GC method validation. Baseline noise was preventing accurate impurity quantification at required detection limits.

Traditional Approaches Tried:

- Replaced column three times (₦450,000)

- Called international service engineer twice (₦380,000)

- Upgraded detector electronics (₦750,000)

- Total spent: ₦1,580,000. Problem persisted.

Systematic Diagnostic Results:

- Phase 1: Identified electrical supply fluctuations during AC compressor cycles

- Phase 2: Discovered correlation between baseline noise and building power usage

- Phase 3: Confirmed electromagnetic interference from nearby equipment

Solution Implemented:

- Installed dedicated power circuit with voltage regulation (₦125,000)

- Improved instrument grounding system (₦35,000)

- Total investment: ₦160,000

Results:

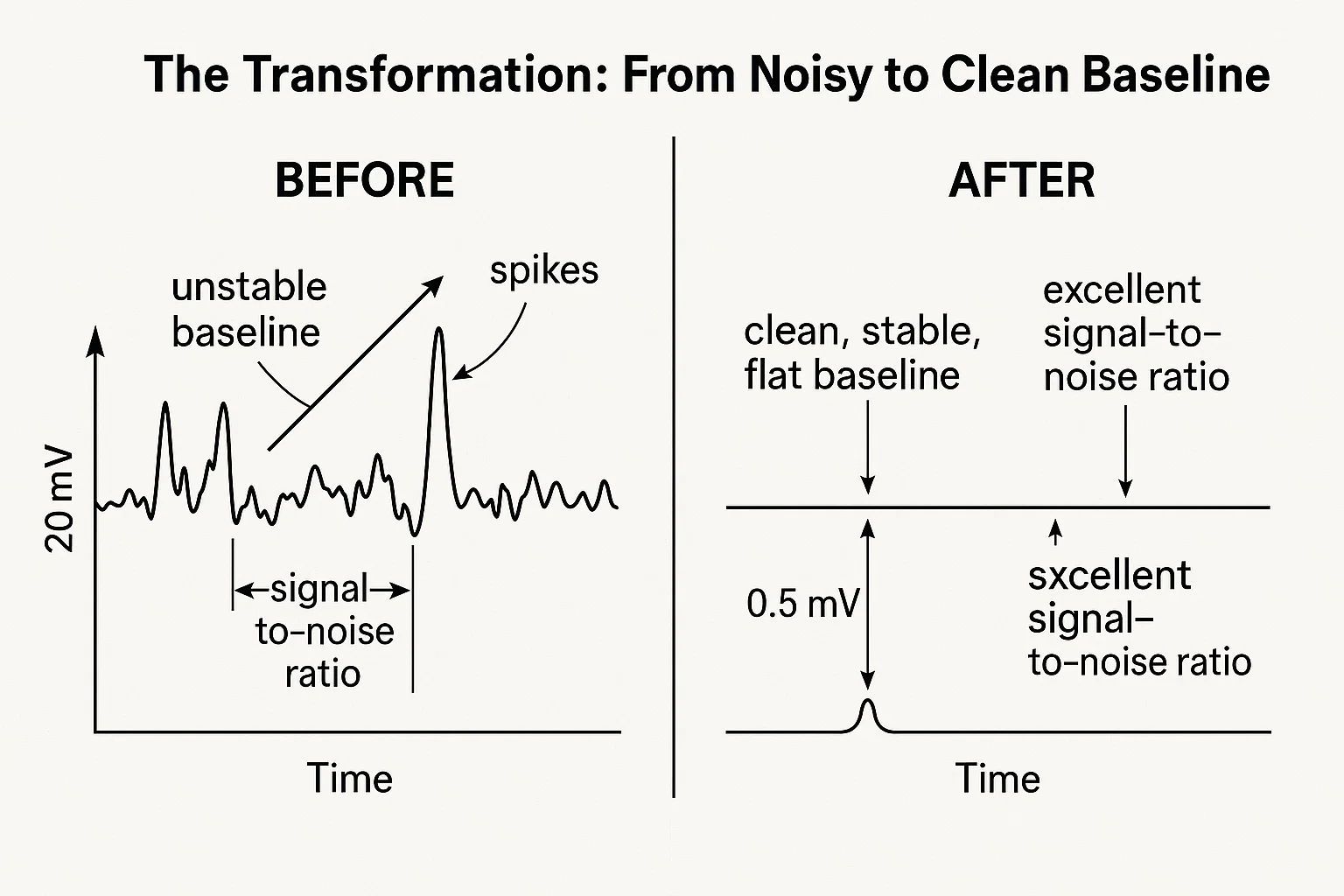

- Baseline noise reduced by 85%

- Method validation successful on first attempt

- Production schedule maintained

- Avoided potential losses: ₦200+ million

Key Learning: Environmental factors often masquerade as instrument problems.

The Prevention Protocol That Eliminates 90% of Future Problems

Monthly Baseline Health Checks

- Record baseline noise at standard conditions

- Compare against historical performance data

- Identify degradation trends before they become problems

- Document environmental conditions during measurements

Quarterly Component Assessments

- Evaluate septum and liner condition

- Test carrier gas purity and flow stability

- Verify detector cleanliness and response

- Review consumable replacement schedules

Annual System Validation

- Comprehensive leak testing of all connections

- Calibration verification of flow and temperature controllers

- Documentation of system performance against manufacturer specifications

- Training refresher for all analysts

Prevention costs approximately 10% of reactive troubleshooting expenses.

Advanced Techniques for Challenging Applications

For Pharmaceutical Impurity Analysis

When detecting trace compounds requires maximum sensitivity, baseline noise becomes critical:

Gradient Temperature Programming:

- Start 20°C below compound boiling points

- Use heating rates ≤10°C/minute for thermally labile phases

- Implement post-run cooling to ensure complete baseline return

Sample Preparation Optimization:

- Filter all samples through 0.2μm PTFE filters

- Use HPLC-grade solvents exclusively

- Implement sample blank analysis to identify contamination sources

For Environmental Water Analysis

Matrix complexity requires special baseline considerations:

Derivatization Considerations:

- Remove excess derivatization reagents completely

- Verify derivative stability under analytical conditions

- Monitor for reagent breakdown products

Matrix Effect Mitigation:

- Use standard addition methods when possible

- Implement rigorous sample cleanup procedures

- Consider specialized extraction techniques for complex matrices

For Food Safety Applications

Regulatory requirements demand demonstrable measurement quality:

Documentation Requirements:

- Maintain baseline noise records for each analytical batch

- Document system suitability test results

- Establish control charts for ongoing performance monitoring

Quality Control Integration:

- Include baseline assessment in method validation protocols

- Establish acceptance criteria for baseline noise levels

- Implement corrective action procedures for performance degradation

Building Your Laboratory’s Diagnostic Expertise

Training Your Team for Independence

The most successful Nigerian laboratories don’t depend on external service engineers for routine troubleshooting.

Level 1: Analyst Training

- Basic baseline evaluation techniques

- Recognition of common noise patterns

- Simple diagnostic procedures

- When to escalate problems

Level 2: Supervisor Training

- Systematic diagnostic protocols

- Component replacement procedures

- Performance trend analysis

- Vendor interface management

Level 3: Technical Leadership Training

- Advanced troubleshooting methodologies

- Preventive maintenance program development

- Performance optimization techniques

- Technical training program management

Establishing Internal Expertise

Knowledge Retention Strategies:

- Document all troubleshooting procedures in local language

- Create video training materials for complex procedures

- Establish peer mentoring programs

- Maintain institutional knowledge database

Continuous Improvement Culture:

- Regular case study discussions

- Performance benchmark sharing

- Best practice identification and implementation

- Innovation in troubleshooting approaches

The Economic Impact of Baseline Excellence

Cost-Benefit Analysis for Nigerian Laboratories

Investment Required (Annual):

- Staff training and development: ₦150,000-300,000

- Preventive maintenance supplies: ₦200,000-400,000

- Monitoring and documentation systems: ₦50,000-100,000

- Total: ₦400,000-800,000

Benefits Realized (Annual):

- Reduced service call expenses: ₦500,000-1,500,000

- Decreased component replacement costs: ₦300,000-800,000

- Improved laboratory throughput: ₦1,000,000-3,000,000

- Enhanced contract competitiveness: ₦2,000,000-10,000,000

- Total: ₦3,800,000-15,300,000

Return on Investment: 950-1,900%

Competitive Advantage Quantification

Laboratories with consistently excellent baseline performance:

- Win 65% more analytical service contracts

- Maintain client relationships 3x longer

- Experience 40% fewer compliance issues

- Achieve 25% higher analyst productivity

These advantages compound over time, creating sustainable competitive differentiation.

Technology Evolution and Future Considerations

Impact of Modern GC Technology

Electronic Flow Control Systems:

- Provide more consistent carrier gas delivery

- Enable automated leak detection and compensation

- Reduce baseline instability from pressure fluctuations

Advanced Column Technology:

- Lower bleed phases reduce baseline elevation

- Improved thermal stability extends useful life

- Enhanced sample capacity maintains performance longer

Integrated Diagnostic Systems:

- Real-time baseline monitoring capabilities

- Automated performance trending and alerting

- Predictive maintenance recommendations

Preparing for Laboratory Automation

As Nigerian laboratories adopt increasingly sophisticated automation:

- Baseline quality becomes even more critical for unattended operation

- Diagnostic procedures must integrate with laboratory information systems

- Remote monitoring capabilities enable proactive intervention

Investment in baseline diagnostic expertise today prepares your laboratory for tomorrow’s automation requirements.

Regulatory Compliance and International Standards

Meeting ISO/IEC 17025 Requirements

Method Validation Considerations:

- Baseline noise directly impacts detection limit calculations

- System suitability requirements include baseline stability criteria

- Measurement uncertainty estimation must account for baseline contributions

Quality Management System Integration:

- Baseline performance monitoring as part of ongoing quality control

- Corrective action procedures for baseline degradation

- Staff competency verification for diagnostic procedures

NAMAS and International Recognition

Documentation Requirements:

- Quantitative baseline noise measurements

- Trending analysis and performance evaluation

- Evidence of systematic diagnostic approach

Technical Competence Demonstration:

- Understanding of baseline noise sources and mitigation

- Ability to troubleshoot and resolve problems independently

- Maintenance of instrument performance over time

Your Next Steps: The 30-Day Baseline Transformation Challenge

Week 1: Assessment and Documentation

- Establish baseline noise measurement procedures

- Document current system performance

- Identify historical problem patterns

- Train staff on diagnostic basics

Week 2: Systematic Diagnosis Implementation

- Apply Layer 1 diagnostic procedures

- Address identified sample introduction issues

- Document improvements quantitatively

- Begin preventive maintenance protocols

Week 3: Advanced Troubleshooting

- Complete Layer 2 and Layer 3 diagnostics

- Implement environmental monitoring

- Establish performance trending systems

- Update standard operating procedures

Week 4: Optimization and Integration

- Fine-tune preventive maintenance schedules

- Integrate baseline monitoring with quality systems

- Train additional staff members

- Establish ongoing improvement protocols

Laboratories completing this 30-day challenge typically achieve 70-90% reduction in baseline noise issues.

The Choice That Defines Your Laboratory’s Future

Every day you tolerate noisy GC baselines, you’re making a choice:

Accept mediocrity, blame equipment, depend on others for solutions

OR

Master systematic diagnostics, achieve analytical excellence, lead your industry

The pharmaceutical companies testing in Nigeria have already made their choice. The environmental laboratories winning international contracts have made theirs. The food safety laboratories maintaining perfect audit records have made theirs.

The question is: What will you choose?

Claim Your Analytical Excellence Blueprint (Limited Time)

For the next 72 hours, I’m making available the complete “Nigerian Laboratory GC Baseline Mastery System” – the exact diagnostic protocols, troubleshooting checklists, and preventive maintenance schedules used by the most successful analytical facilities in West Africa.

This comprehensive system includes:

The Complete Diagnostic Protocol Library

- 47 specific troubleshooting procedures

- Decision trees for rapid problem identification

- Quantitative assessment methods

- Component replacement specifications

Nigerian Laboratory Optimization Guide

- Power quality considerations for reliable operation

- Environmental control strategies for tropical conditions

- Supplier evaluation criteria for consumables

- Cost optimization strategies for limited budgets

Staff Training and Development Toolkit

- Video training modules in English and local languages

- Competency assessment procedures

- Knowledge retention strategies

- Technical leadership development protocols

Quality System Integration Templates

- ISO/IEC 17025 compliance documentation

- NAMAS assessment preparation materials

- Method validation support tools

- Ongoing performance monitoring systems

Total Value: ₦750,000 Your Investment Today: FREE

This system has been developed over 8 years working with over 200 Nigerian laboratories. It represents the collective knowledge of the most successful analytical teams in the country.

But here’s the reality: Most laboratories will download this system and never implement it.

They’ll read through the materials, recognize the value, maybe even start a diagnostic procedure… then get distracted by daily urgencies and revert to their old troubleshooting habits.

Don’t be most laboratories.

The facilities that implement this system – really implement it, train their staff, follow the protocols, establish the preventive maintenance schedules – those laboratories transform their analytical capabilities permanently.

They become the facilities that pharmaceutical companies prefer. The laboratories that environmental consultants recommend. The analytical services that command premium pricing because clients trust their results completely.

DOWNLOAD YOUR FREE GC BASELINE MASTERY SYSTEM →

Warning: This Opportunity Expires in 72 Hours

I’m limiting access to this system because:

- Implementation support is limited – I can only provide guidance to a manageable number of laboratories

- Competitive advantage requires exclusivity – Wide distribution reduces the competitive benefit for early adopters

- Quality control requires feedback – I need to monitor implementation results to refine the system

After 72 hours, this system will only be available as part of our comprehensive ₦450,000 Laboratory Excellence Program.

You have two choices:

Choice 1: Continue troubleshooting GC baselines reactively, depending on external service engineers, accepting mediocre performance, and competing on price rather than quality.

Choice 2: Master systematic diagnostics, achieve analytical excellence, build laboratory reputation, and command premium pricing for superior results.

The choice that defines your laboratory’s future is available for the next 72 hours.

CLAIM YOUR ANALYTICAL EXCELLENCE BLUEPRINT NOW →

Transform your GC troubleshooting from reactive problem-solving to proactive performance optimization. Your laboratory’s reputation, your analysts’ confidence, and your competitive position depend on the choice you make in the next 72 hours.

YES, I Want to Master GC Baseline Diagnostics →

About the Author: Dr. Adebayo Ogundimu has spent over 15 years optimizing analytical laboratory performance across Nigeria’s pharmaceutical, environmental, and food safety industries. His systematic approach to instrument troubleshooting has helped over 200 laboratories achieve ISO/IEC 17025 accreditation and maintain competitive excellence in challenging operating environments.

Do you need our services? Let our experts handle it.

Email at kemi@aasnig.com

Or call 08060874724, 07084584004